header

News

A Single Chip Reshapes the Paradigm of Nanomaterial Synthesis

- WRITER 학무부총장실

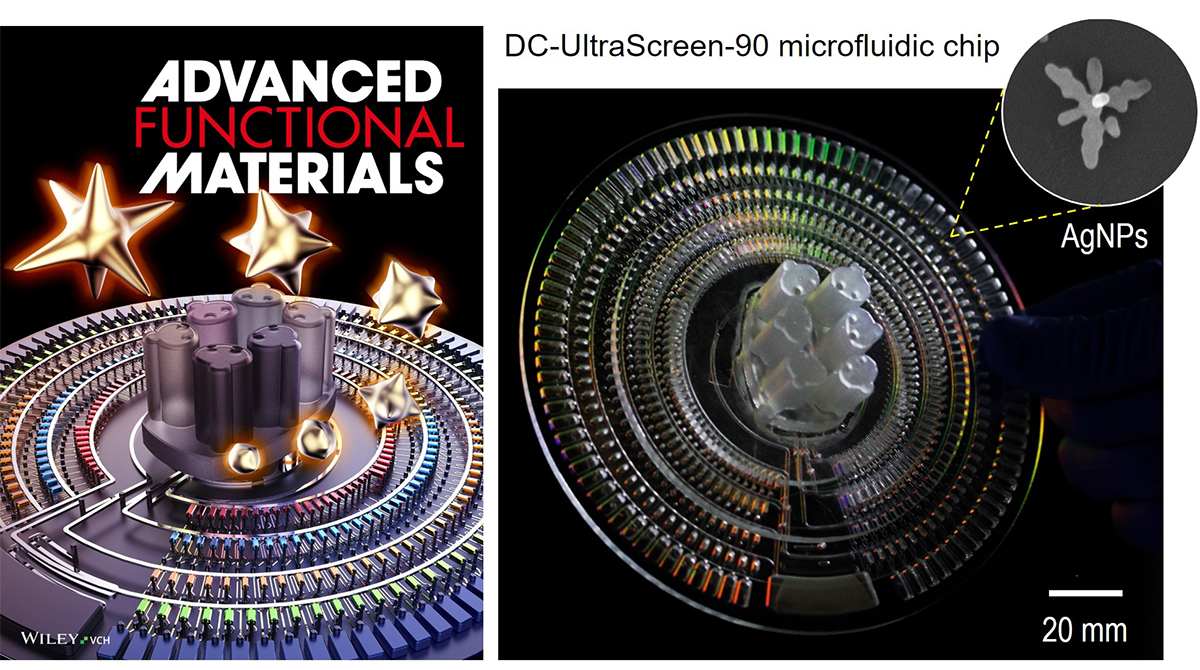

A research team led by Professor Tae Seok Seo of the Department of Chemical Engineering has developed DC-UltraScreen-90, a microfluidics-based nanomaterial screening platform capable of generating 90 reaction conditions in just three minutes

The system is a high-throughput device capable of automatically generating 90 reaction conditions within just three minutes, significantly improving the speed and reproducibility of nanoparticle synthesis research. By enabling rapid exploration of diverse material combinations, it is drawing attention as a powerful new research tool.

Automating synthesis: moving beyond manual experimentation

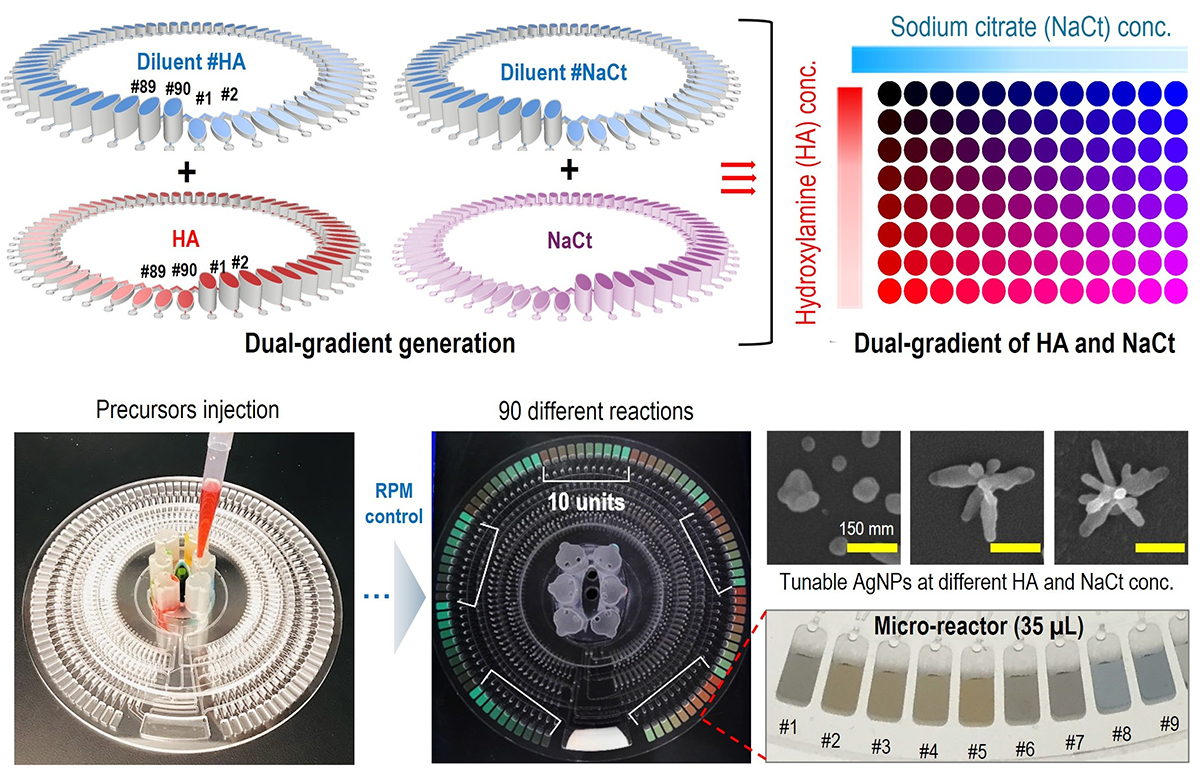

At the core of the research is microfluidic technology, which enables precise manipulation of small liquid volumes within microscale channels. This approach ensures uniform reaction environments while substantially reducing reagent consumption. The research team combined this technology with a centrifugal microfluidic structure, designing a system in which liquid transport, mixing, and dispensing are driven solely by rotational motion—without the need for external pumps or complex instrumentation. The resulting device is the compact centrifugal microfluidic chip known as DC-UltraScreen-90.

The chip takes the form of a plastic disk smaller than the palm of a hand. Its internal architecture is meticulously designed to control how liquids are divided and flow through the system. During high-speed rotation, reagents are precisely metered, while slower rotational phases allow solutions to be gently distributed, preventing particle aggregation and enabling uniform reactions.

To evaluate the platform’s performance, the team used silver-based nanomaterials as test samples. Silver nanoparticles (AgNPs) typically exhibit spherical shapes, whereas silver nanostars (AgNSs) form sharp, multi-branched structures. Because their morphologies change markedly with reaction conditions, these materials serve as an ideal model system. Their physical properties and application potential differ significantly, making them useful across a wide range of fields, including sensors, bioanalysis, and catalysis. Comparing nanomaterials with clearly contrasting morphologies enabled the team to verify the platform’s ability to precisely control nanoparticle structures. A key element in this validation was the automated concentration-combination capability of DC-UltraScreen-90.

Universal applicability: a versatile platform for diverse material systems

The research team further demonstrated the platform’s reliability by confirming that optimal conditions identified on the chip could be scaled up to larger reaction volumes while producing nanoparticles with nearly identical morphologies. This result shows that DC-UltraScreen-90 is not merely a rapid screening tool, but a practical platform capable of translating optimal conditions to large-scale synthesis.

With low dependence on specialized equipment, simple operation, minimal reagent consumption, and high reproducibility, DC-UltraScreen-90 can be readily adopted even by small research laboratories. Beyond nanoparticle synthesis, the platform shows strong potential for expansion into a wide range of research areas, including drug combination screening, biodiagnostics, and combinatorial materials development. Professor Seo commented, “This platform not only enhances the speed and reproducibility of nanomaterial research but also serves as a foundational technology that allows researchers to easily explore much broader combinations of conditions. We expect it to significantly improve the efficiency of nanotechnology-based materials development as it expands to diverse material systems.” The research findings were published as a Back Cover article in Advanced Functional Materials (IF=19.0) under the title, “From Spin to Star: Ultrafast Dual-Gradient Centrifugal Microfluidics for Scalable High-Throughput and Combinatorial Nanomaterial Synthesis.”