header

News

EVs Now Charge in Just 15 Minutes

- WRITER 학무부총장실

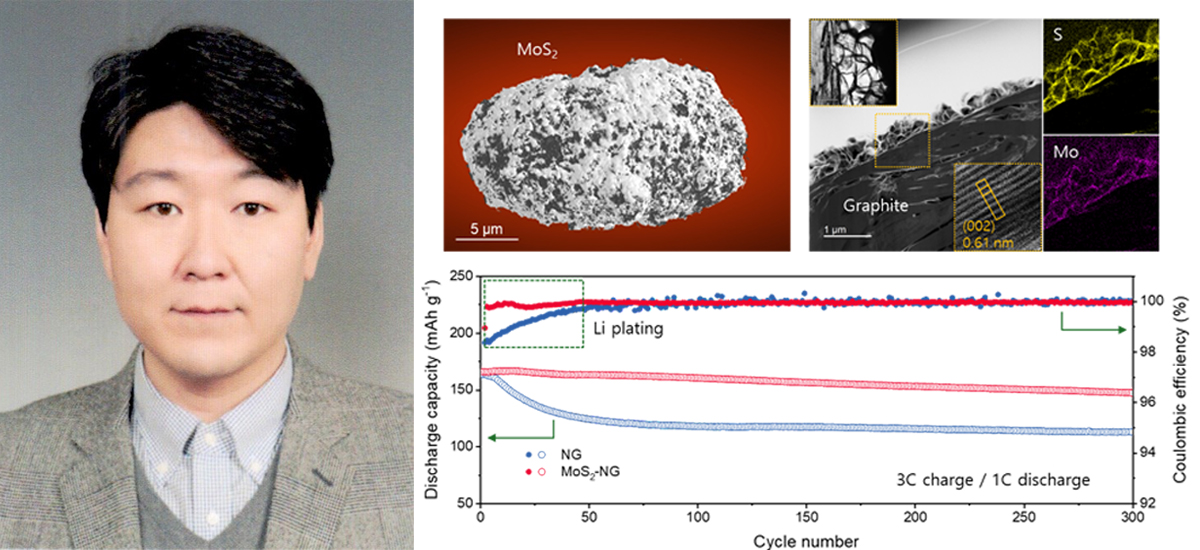

A research team led by Professor Min-Sik Park of the Department of Advanced Materials Engineering has developed a high-performance natural graphite anode material for lithium-ion batteries

While the electric vehicle (EV) market is expanding rapidly, limitations in driving range and charging time continue to hinder its competitiveness with internal combustion engine vehicles. To accelerate EV adoption, the development of ultra-fast charging technologies that overcome these constraints has become increasingly critical.

In collaboration with Professor Jung Ho Kim from the University of Wollongong, Australia, and Professor Jong-Won Lee from the Division of Materials Science and Engineering at Hanyang University, a research team led by Professor Min-Sik Park of the Department of Advanced Materials Engineering has developed a high-performance natural graphite anode material for lithium-ion batteries—a core component in the advancement of electric vehicle. The newly developed anode dramatically improves fast-charging capability without compromising energy density, while also enhancing battery stability and lifespan. The study was recognized for its excellence and published in the February issue of Advanced Materials (Impact Factor 27.4) under the title, “Toward Fast‐Charging and Dendritic‐Free Li Growth on Natural Graphite Through Intercalation/Conversion on MoS2 Nanosheets.”

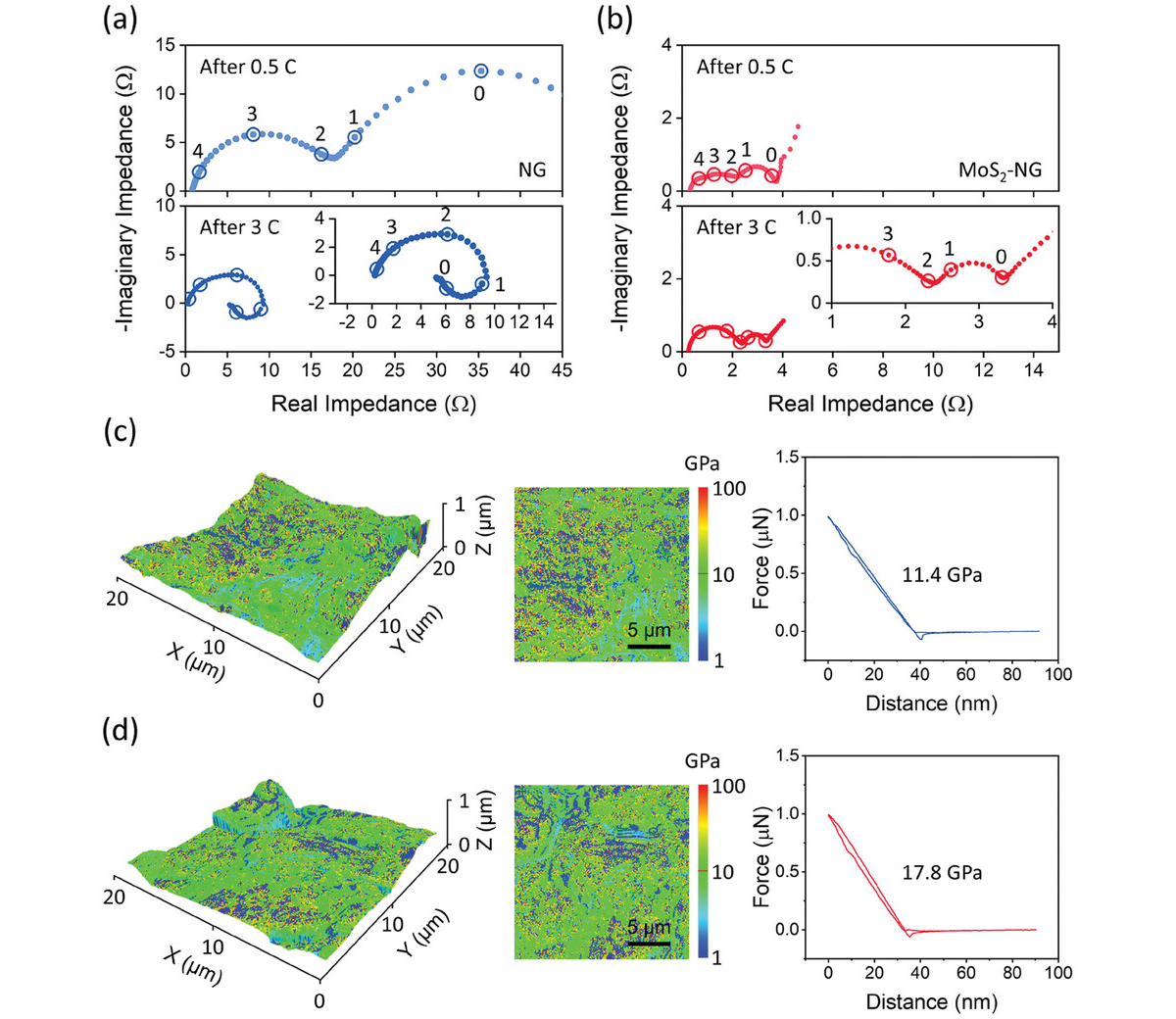

Conventional graphite anodes used in EV batteries often suffer from high interfacial resistance, which leads to lithium metal plating during fast charging—a phenomenon that undermines battery performance and raises serious safety concerns. To solve this, the research team optimized the surface characteristics of cost-effective natural graphite through advanced interface engineering. By applying a novel functional coating layer, they successfully reduced interfacial resistance, enabling rapid and stable charging.

The key to enhancing fast-charging performance lies in the precise analysis and optimization of interfacial reactions on the graphite surface. The team employed advanced characterization techniques such as ex-situ Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), and time-of-flight secondary ion mass spectrometry (ToF-SIMS) depth profiling to investigate the electrochemical conversion mechanisms across different voltage ranges. “By analyzing microstructural changes at various reaction potentials, we gained a deeper understanding of the electrochemical behavior of the functional coating layer,” said Professor Park.

The team also validated the battery’s performance. After 300 charge–discharge cycles, the lithium-ion batteries maintained 88.8% of their capacity and operated stably without lithium metal plating. Remarkably, even with low-cost natural graphite, the battery achieved 80% charge in just 14.7 minutes, marking a significant advancement in fast-charging technology. “This breakthrough is poised to become a foundational technology not only for electric vehicles but also for energy storage systems and high-power electronic devices that require both high-speed charging and long service life,” said Professor Park. It is worth noting that this study was supported by the Ministry of Science and ICT of Korea and the National Research Foundation of Korea (NRF) through the Basic Research Program and the Original Technology Development Program.