header

News

Kyung Hee Researchers Develop Next-Generation Intelligent Material That Adapts to Its Environment

- WRITER 학무부총장실

A research team led by Professor Yoonseok Park of the Department of Advanced Materials Engineering has created a new class of muscle-inspired mechanical metamaterials whose rigidity can be actively adjusted in real time using magnetic fields

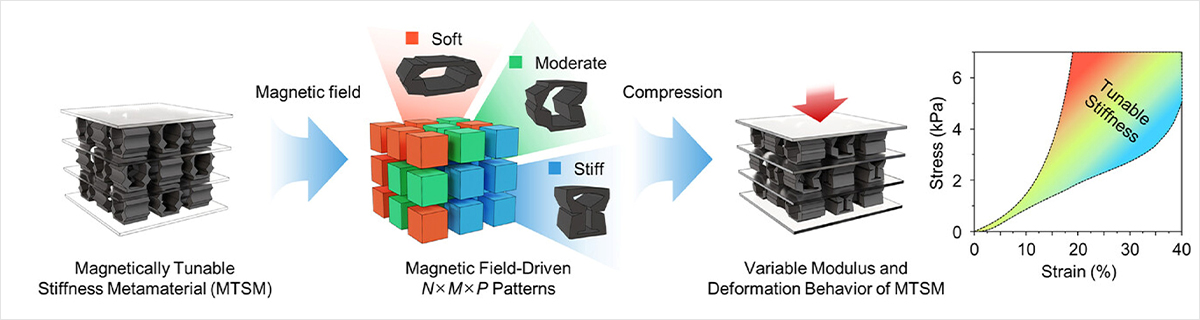

Drawing inspiration from the sarcomere—the fundamental contractile unit of muscle—the team designed a structure that can rapidly shift from soft and compliant to firm and load-bearing. Unlike conventional systems that simply switch between “on” and “off,” the material supports three discrete mechanical states (soft, medium, hard), delivering far greater control and responsiveness.

Magnetic control over mechanical behavior

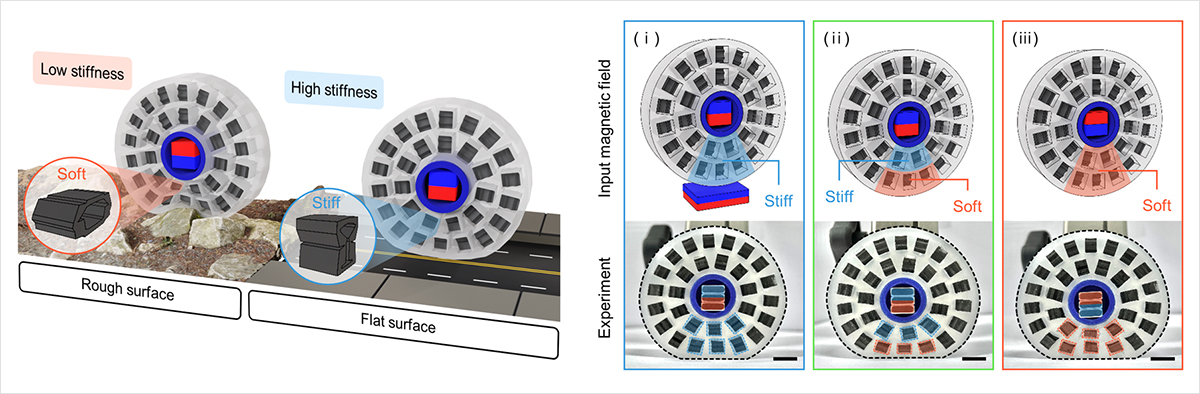

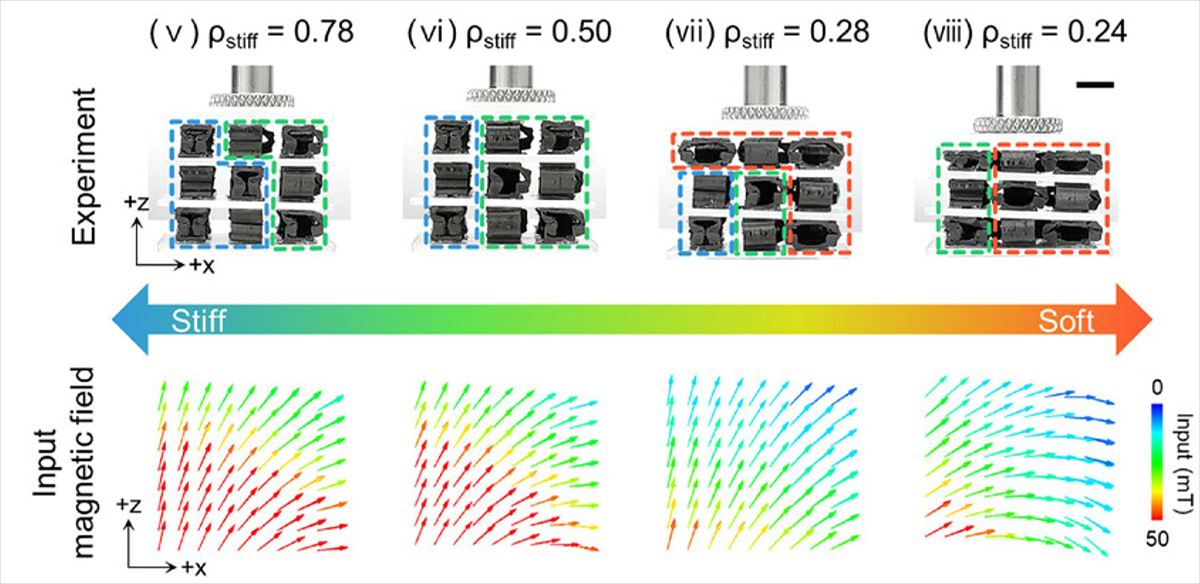

To build the material, the researchers formulated a printable ink that blends neodymium-based magnetic particles (NdFeB) with a highly elastic block copolymer, SIS (styrene-isoprene-styrene). Using 4D printing, they fabricated a magneto-responsive architecture that can be “dialed in” on demand. The resulting platform—a magnetically tunable stiffness metamaterial (MTSM)—reacts to an external magnetic field in about 0.1 seconds and can vary its mechanical stiffness by more than 390%. When the units are assembled into a 3D array, different regions can be set to different rigidity levels depending on field direction and strength. In other words, the same structure can behave like a cushion in one area and a brace in another. This level of spatial and temporal control suggests that the material is not just deformable, but actively reconfigurable.

To demonstrate how this works in practice, the team built an adaptive wheel system whose behavior changes with the terrain. On rough or uneven ground, the wheel softens locally to absorb impact and climb over obstacles; on smooth surfaces, it stiffens to maintain stability and efficient rolling. This kind of terrain-aware response is directly relevant to soft robotics, autonomous mobility platforms, and artificial muscle systems, where machines are expected to move through unpredictable environments and still maintain precision and reliability.

“Our work moves beyond passive ‘shape-changing’ materials,” said Professor Park. “We are laying the groundwork for truly intelligent matter—systems that can program, update, and reorganize their own mechanical properties in response to what is happening around them.” Industries such as soft robotics and bioelectronics increasingly need materials that do more than just bend. They need structures that sense conditions, adapt their physical behavior, and keep functioning without manual intervention. Traditional fixed-property materials struggle to meet that demand, especially in complex, real-world settings.

This study, titled “Rapidly Programmable Magneto-Mechanical Metamaterials Inspired by the Sarcomere Structure,” was published in Advanced Materials (impact factor: 29.4) on August 28, 2025, under the title, “Bioinspired, Rapidly Responsive Magnetically Tunable Stiffness Metamaterials.” The work was conducted in collaboration with Dr. Seung Kwon Seol and his team at the Korea Electrotechnology Research Institute (KERI).